|

Our

engines, technical data and describtions Overview and Background Scale

model raceboats – called powerboats – became bigger

and bigger in the last few years. We suppose at first, that the owners want

to see something big on the water and second that big boats can better handle

big waves. And: sometimes bigger is better…… An arms

race began and the engines became bigger, stronger also and more than one was

installed in a big boat. But: if the modelling enthusiast wants to build a

really big boat like a 84” Apache, these little engines were a bit too small.

Even some modelers decided to install

scooter-engines into their boats. These engines have large displacements and

are heavy metal monsters. Plus: massive pistons and rods may cause big

vibration issues. Remember:

we are talking about modelling……. Years

ago multi-cylinder nitro engines have been introduced. We suppose that caused

by carb adjusting issues and costs these are low in count worldwide. To improve

this situation we decided to design and build a multi cylinder powerhouse

family. Our

engines are based on the very robust and well known Japanese ZENOAH 260PUM

and their followers like 290PUM or RCMK. Since

2017 we are using parts of ZENOAH 290PUM only. Out of these mass production

engines the following original parts will be used after checking and

partially improving: On CNC-machines we perform some

modifications to increase the output power. All engines will be installed on a test rig before

shipment, carbs will be adjusted. For symmetric packages (if 2 engines will be used) a

mirror like (symmetrically) assembly could be done on customer's request.

Rotating direction is selectable also. Support:

all our

customers will get an installing and run-in support on request for free via

mail.

The powertrain

components: 1. RAT

HOUSE engine (powerplant) 1.1. crank house and mounts All

parts will be milled out of strong aluminium and could be anodized on

customers request. Watercooling of the housing is

recommended and prepared. 1.2. crank shaft is 100% new designed, because we do not

like to connect the mass production cranks with clamping or key technique.

The hardening was done with help by formula 1 technicians in Switzerland. 10

ball bearings are on the RAT’s crank. The bearing suppliers are INA or

FAG. 1.3. ignition We use the self developed electronic

ignition Power-Spark (see web-catalog). Caused by

this we do not need to install both red source coils and very slim assemblies

are possible from now on. 2. RAT

HOUSE exhausts 2.1. tuned pipes All existing power pipes on the market

will fit to RAT HOUSE. 3. RAT HOUSE clutch Worldwide the 52mm clutch is in usage,

this clutch will be used in model cars also. Caused by the big power and

torque of RAT HOUSE the recalculation showed, that we have to use a bigger

65mm one, see web-catalog. 4.

RAT HOUSE transmission/gearbox Caused by the power of RAT HOUSE it would

be impossible to make a single prop configuration w/o any rpm change. A splitter

gearbox was developed which could be ordered with 28% more rpm at the

outputs. Possible usage: - with 2 counter rotating output shafts, called

splitter, could be installed in 2 different positions w/o disassembling:

inside or outside rotating propellors - only with one output, rpm increase - only with one output, rpm increase plus

counter rotating Techical data: - shafts are completely ball beared (6 ball bearings) and hardened - gears and shafts in a one piece design - oil lubricated - shaft seals - power capability up to 40hp, with mild mods up to 50hp. Each single assembled powerplant

will perform a test run on a bench and the carbs will be pre-tuned.

RAT HOUSE could be installed in other

vehicles:

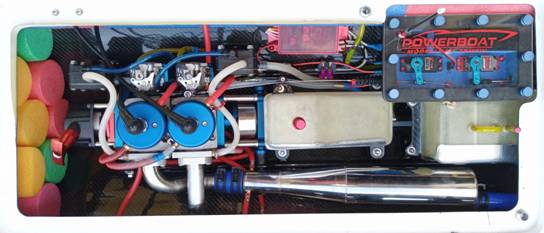

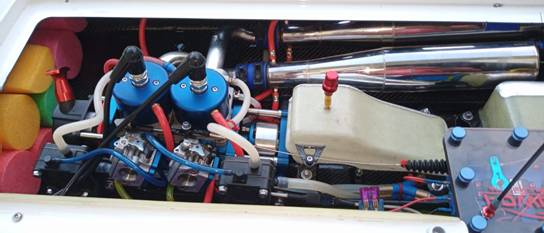

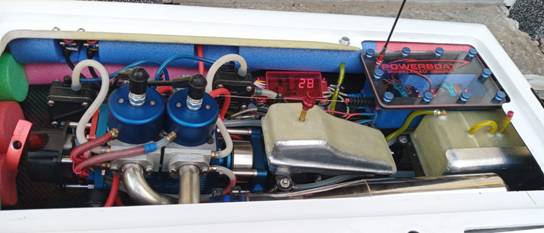

pics with friendly release by Siggi Hartmann MOUSE HOUSE, the

2-cylinder engine (pics

by Henry Dietrich):

The powertrain

components: 1. MOUSE HOUSE engine (powerplant) 1.1. crank house and mounts All

parts will be milled out of strong aluminium and could be anodized on

customers request. Watercooling of the housing is

recommended and prepared. 1.2. crank shaft Is 100% self designed, because we do not

like to connect the mass production cranks with clamping or key technique.

The hardening was done with help by formula 1 technicians in Switzerland. 6

ball bearings are on the MOUSE’s crank. The bearing suppliers are INA or

FAG. 1.3. ignition Engines will be prepared for the mass

production CDI ignition of ZENOAH. or we deliver with the electronic ignition

Power-Spark (see web-catalog). Open homepage in a new

window? click

here Errors excepted. All trademarks are

property of their owners. |